Description

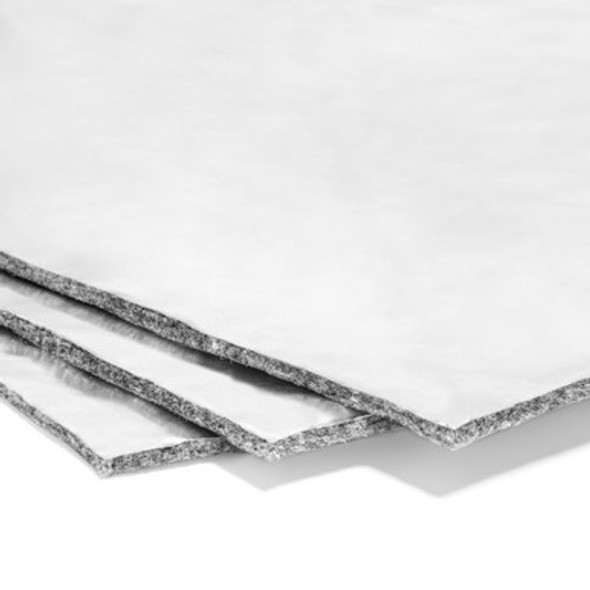

Mega Block - Hydrophobic Foam + Heat Shield

Keep your cabin cool with Mega Block, specifically designed to be a best-in-class heat shield by combining an aluminum reflective barrier with the excellent automotive heat insulation attributes of melamine foam. Mega Block is hydrophobic, lightweight, and flexible while reflecting 98% of radiant heat energy. Use it on the engine side of the firewall, as hood insulation, or any vehicle needing heat control including engine compartment insulation for your boat.

- 0.5 inch thick hydrophobic melamine foam with an aluminum foil-faced composite bonded on top

- Lightweight, flexible, water resistant, and Class A fire rated

- Reflects 98% of radiant energy

- Each sheet is 24” x 24” (4 Sq Ft) and weighs about 1/2 of a pound

- Thermal range: -40 F to 1000 F

- Resists organic solvents, odor free, and meets smoke, fire, and toxicity standards

- Aerospace grade foam and heat shield (R-value per inch: 4.16)

- Made in Germany with hydrophobic process completed in the USA

Product Usage

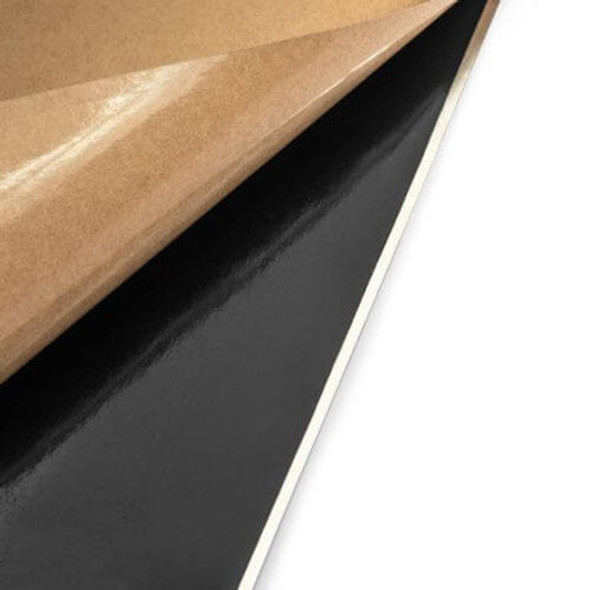

- Always face foil side of the product towards the heat source

- Easy to apply with our peel & stick adhesive backing. You need to apply enough pressure for your fingers to "feel" the adhesive bonding to the metal surface.

- Install at least 2” from the heat source. We recommend foil insulation tape on the edges to protect the foam.

- Used in non-automotive locations as well, like generator boxes or a soundproof server rack

- Hood - cover entire lid with foil facing the engine

- Firewall - engine side

- For rear-engine design layouts, apply to the vehicle's back wall.

| Flammability Ratings: | Description: | Rating: |

| UL 94 HF-1 | Horizontal Burning | Pass |

| UL 94 V-0 | Vertical Burning | Pass |

| FAR 25.853 (a, i) | 60 Sec Vertical |

Burn Time (Avg): 0 Seconds Burn Length (Avg): 2” Drip Extinguish Time: No Drip |

| FAR 25.856, BSS7365, AITM 2.0053 | Radiant Panel |

After Flame: 0 Seconds Flame Propagation: < 1” |

| ASTM 662-83, BSS7238 | Smoke Generation |

Flaming: Ds (1.5 min) = 57 Ds (4.0 min) = 77 |

| BSS7239 | Toxicity | Pass |

| ASTM E 84 | Steiner Tunnel, 1inch thick |

Flame Spread < 25 Smoke Developed < 50 |

| ASTM E 162-83 | Surface Flammability |

Flame Spread factor 1.83 Heat Evolution factor 2.50 Flame Spread index 4.62 |

| DIN 5510 |

Flammability: S4 Smoke: SR2 Drips: ST2 |

Foil Heat Shield Specifications

| Base Fabric Type: | Plain Weave Fiberglass |

| Aluminum Foil thickness: | 0.001 inches |

| Composite Characteristics: | |

| Thickness (ASTM-D1777-96): | 0.02” (Nominal) |

| Weight (ASTM-D-3776-96): | 0.1225 lb/sft (Typical) |

| Tensile Strength:(ASTM-D-5035-95): | Warp-75 lb/in |

| Fill- 50 lb/in | |

| Flame Resistance (FED 191/5903-2): | |

| Flame Out | 1 sec max |

| Afterglow | 1 sec max |

| Char Length | 1 inch max |

| Temperature Range: | |

| Composite | *-40°F to 1,000°F |

|

1000°F requires 2” between the heat shield and the heat source |

*PSA Temperature Range: -40°F to 450°F |

Acoustical Properties

ASTM E1050 testing method used to record acoustical absorption coefficients at various thicknesses and frequencies.

Frequency (Hz)

| Foam Thickness: | 125 | 250 | 500 | 1000 | 2000 | 4000 |

| 0.25 in. | 4 | 5 | 10 | 20 | 39 | 81 |

| 0.50 in. | 11 | 12 | 25 | 42 | 77 | 94 |

| 1.0 in. | 18 | 23 | 50 | 82 | 99 | 99 |

| 2.0 in. | 31 | 60 | 75 | 90 | 100 | 100 |

| 3.0 in. | 42 | 67 | 81 | 96 | 100 | 100 |

| 4.0 in. | 53 | 80 | 90 | 99 | 100 | 100 |